After using your sewing machine for a while and experimenting with various stitches, you’ve realised that some seams are poorly sewn or that occasionally the stitches skip. These symptoms can point to a needle issue.

In this post, we’ll look at the various needle types and which ones are best for your sewing machine and sewing job. Needles come in a variety of shapes and sizes, which can be confusing when it comes time for a needle change.

The very first thing to do is check your user manual to see which size needles are recommended for your sewing machine. It’s not uncommon for people to use the incorrect needle on their sewing machine. But doing so can cause the needle to break, make the fabric tricky to work with, and result in shoddy stitching.

Our needle size guide for sewing machines will ensure that you never encounter this issue again.

We have listed the various kinds of needles that are available, along with the materials and threads that each type is most suited for. Even if you’re an experienced sewer who already knows everything there is to know about needles, you should still read this. In the process of self-exploration, you might find the needle that changes your life forever.

How to Spot a Blunt or Wrong-Sized Needle?

- The needle frequently breaks

- The needle becomes bent or warped

- The sewing machine skips stitches

- The top thread snaps

- The machine becomes noisy

When it comes to sewing, a properly sized needle is the key to producing flawless, uniform stitches without tearing the fabric. It Th will provide strong seams that will not easily break.

Before we go into the specifics, keep in mind that the needle for a sewing machine and the needle for hand stitching are not the same in terms of use or form. We welcome you to read the article on the fundamental sewing tools here to learn more.

The majority of the needle brands that are sold on the market are standardised, meaning that they work with a variety of sewing machine brands. Be cautious, as some brands, such as Singer, require particular needles.

When it comes to brands, there are unbranded needles and branded needles that are more known for their quality, such as Schmetz, Hemline, Milward, Singer, YKK, Organ, or Prym. Needles are always described by numerical identifiers that stand in for their sizes – that we’ll get into shortly.

Needles with lower numbers are thinner and lighter and are used for sewing finer fabrics, while those with higher numbers are designed to work with thicker materials.

In addition to the numbers, the needles are labelled with the name of the fabric they are suited for, such as Jersey, Stretch, Denim, or Leather. Some needles will have the job type they are best suited for, such as quilting, embroidery, or overcasting.

Related: Are Overlocker Needles Different to Sewing Machine Needles?

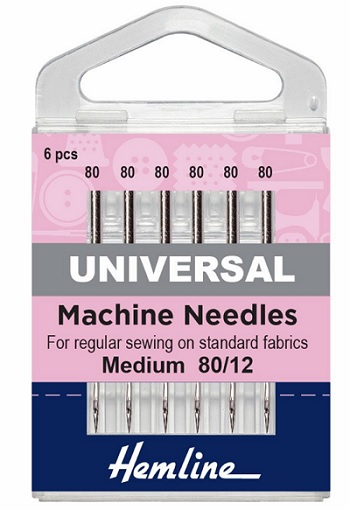

What do the Numbers Mean on the Needle Box?

The numbers represent the needle’s diameter in hundredths of an mm. For example, a universal 80 needle has a diameter of 80/100mm = 0.8mm. Some needles feature two numbers, such as 70/10, 80/12, 90/14, and 100/16; these are merely European and American measuring units, respectively.

Also, some needles have colour coding and a chart to let you know which fabrics are best suited to the needle.

Since needle length is standard, the diameter measurement is all that’s needed to determine which needle is being used.

Universal Sewing Needles

Generally speaking, this is the standard go-to needle, and while it will fit any sewing machine, and may be used with any seam and fabric, it is not advised for elastic or stretchy materials.

They are normally numbered size 60 to 100, however, the universal needle is number 80 by default. When purchasing a sewing machine, this needle is frequently included.

Universal Needle Size Guide

- Size 60 (very thin): chiffon, cotton, lace, silk, synthetic veil, tulle, organza

- Size 70 (fine): linen veil, viscose canvas, taffeta, cambric, fine crepe, organdi

- Size 80 (standard): poplin, fine velvet, canvas, crepe, wool, linen, quilting

- Size 90 (thick): dens wool, velvet, canvas, jacquard, twill, denim

- Size 100 (extra thick): leather, thick twill, thick jacquard, upholstery, denim

Needles for Jersey and Stretch

Jersey and Stretch are the types of fabrics most used in industrial textiles. These fabrics are stretchable which requires the use of a range of dedicated needles which are numbered from 65 to 90. Jersey and Stretch’s needles have rounded tips so as not to damage the fabric.

- Size 65 (very fine): very fine cotton and polyester jersey, silk jersey, viscose jersey

- Size 70 (thin): thin cotton and polyester jersey, medium-thick viscose, thin knitwear

- Size 80 (medium): interlock, sweatshirt, fleece

Super Stretch Needles

Super Stretch Needles: What Are They? For highly elastic, thick fabrics and thick threads, the super stretch needle is the tool of choice. It is designed with a flat shaft, rounded tip, and a scarf region that prevents stitches from skipping and allows for the use of larger threads without breaking or damaging the fabric.

- Size 60 – 65: fine super stretch fabric

- Size 70 – 75: medium super stretch fabric (swimsuits)

- Size 80 – 90: thick super stretch fabric (sportwear)

Stretch materials are much less elastic than super stretch fabrics. They are utilised in the production of sportswear and swimwear. The Super Stretch needles range in size from 60 to 90.

- Fine super stretch fabric in sizes 60–65.

- Medium super stretch fabric in sizes 70-75. (swimsuit type)Thick ultra-stretch fabric in sizes 80-90. (sport type)

Microtex Needles

This needle type has a fine tip that will penetrate very fine or very dense materials without damaging or damaging them. It also allows for flawless stitches for stitching edges that demand considerable precision. Silk fabrics, polyester microfiber, sequin fabric, satin, nylon, polyester, poplin, organza, and taffeta, but also coated materials and metallic foils should be sewn with a Microtex needle.

- Size 60 to 80: for fine to medium fabrics

- Size 90: for medium to thick fabrics

Microtex sewing machine needles are often offered in boxes made up of different sizes.

Needles for Jean and Denim

As you may have guessed, it is the needle range for jeans and denim fabrics that have a thick canvas and a tight mesh. It should be mentioned that traditional sewing machines may not be capable of sewing jeans and denim cloth. In any case, consult the instructions for your sewing machine and do not hesitate to seek guidance from the supplier. Jeans’ needles are numbered from 90 to 110.

- Size 90: jeans and fine denim, medium cotton twill

- Size 100 – 110: jeans and medium denim, thick cotton twill

- Size 130: thick jeans and heavy denim, rugged workwear clothes

Leather Needle Types and Sizes

These powerful needles are used for both genuine leather and counterfeit leather. They have a triangular point that does not influence the structure of the leather as it is passed through the needle. They are numbered 80 through 110.

- Size 80: thin and supple leather or faux leather, lambskin

- Size 90: medium-thick leather or faux leather

- Size 100 – 110: for thick leathers (may require a special heavy-duty machine)

Sewing Needle Anatomy

Needle Eye: The “eye of a needle” is a proverbial expression describing a tiny gap. In the case of a sewing machine needle, it’s the small gap that the thread is “threaded” through. A high-quality needle will have an eye that has been precisely honed to prevent the thread from tearing. Each thread has a certain recommended eye size.

Shank: There is a flat side and a rounded side to the shank; the flat side should be facing the back of your sewing machine. Depending on the type of machine needle, the shank may be totally circular. The needle’s shaft tapers from the shank to the tip.

Needle Shaft: The shaft is the needle’s main body, located above the eye and below the shank. Needle size is quantified in terms of a number or range of integers that correspond to the shaft thickness. A smaller number indicates a thinner needle, while a bigger number indicates a thicker needle.

Point: Needlepoints come in a broad variety of shapes, from ball points for knit textiles to chisel points for leather.

Needle Scaft: Prevent skipped stitches by positioning the hook close to the needle’s eye with the help of a scarf.

More Needles to Consider

Ballpoint needles

You’ll notice that ball-point needle tips are more rounded than a universal needle which will drive cloth fibres apart, rather than cutting them.

Because of this, ball point needles are recommended for use with a wide variety of knit fabrics, including rib knits, cotton knits, interlock, fleece, double knitting, and just about any other type of knitting. Ball point needles work best with polyester and polyester mixed cotton blend threads, with finer threads requiring finer needles.

Needles for Quilting

Quilting needles, like sharps needles, have a strengthened shaft so they can be used through multiple layers of fabric and wadding, but they are significantly shorter in length to facilitate fast and even sewing. Beginners will most likely find a smaller needle such as a size 7 or 8 easier to use but more experienced quilters frequently prefer a bigger choice.

Needles for Embroidery

Machine embroidery threads made of rayon, polyester, or cotton are too thick for standard sewing needles, but they glide effortlessly through embroidery needles because of their larger eyes.

Fabric flexes quickly due to the fast-moving embroidery stitch, which can lead to missed stitches during machine embroidering. Embroidery needles prevent this by limiting the amount of cloth movement through the use of a pontoon scarf with an oversized hump.

Changing Your Sewing Machine Needle

First things first – make sure you’re fitting the correct size and type of needle.

Although it may seem intimidating at first, learning how to change your needle is a crucial skill for any sewer.

The reason is, that a broken or blunt needle might ruin your fabric and your sewing machine.

If you are having issues with your thread getting tangled or your machine dropping stitches, it may be time to switch to a new needle because the old one is probably too dull. This instruction manual is meant to streamline the procedure and help you fix any problems that could result in a damaged or dull needle.

Whether or not the needle has broken or you feel it has gotten blunt, it is generally recommended that you change needles every 5-10 hours of sewing or every two projects.

This ensures that you’ll almost never have to start a project with a dull needle and protects your machine from potential harm, such as bobbin case damage or the needle snapping and so throwing off your stitch timing. If you discover that you are encountering a lot of problems with your needle, it may be prudent to get your machine professionally serviced.

- Grasp the needle with your left hand, and use your right hand to loosen the screw at the needle’s top. If your needle is broken, it is crucial that you keep it from falling into the machine or into the floor. In some cases, a screwdriver may be included with your machine to assist in removing the screw.

- To remove the old, just unclip it from its holding clamp and draw it down and out of the device.

- Place the new needle in the machine so that the flat side of the needle shank is facing the back. To do this, use your left hand to re-insert the needle into the clamp to its highest possible position.

- With your right hand, tighten the screw again to secure the needle. Do not over-tighten it, as this will make it difficult to change the needle in the future, but do not leave it too loose, as this could cause the needle to be left in the fabric while you sew.